PW & WFI POU Heat Exchanger

Point-Of-Use Cooler for pharmaceutical water systems

Benefit

- Instant cold or hot WFI or PW availability at POU

- Continuous flow of hot water keeps it sanitized at all times.

- Automated or manual operation

- PLC with touch Screen HMI with many operating modes

- Fully drainable on product side, with no dead legs

- Easy to install, operate and maintain

- CIP and SIP capable

Design Features:

- Enclosed locking cabinet

- Sanitary tube in tube heat exchanger eliminates risk of cross contamination between product and working fluid

- All product contact surfaces are passivated, less than 0.4 Ra and electropolished

- SS 316L seamless tubes construction

- Full quality documentation provided

- ASME BPE Compliant

- No Internal Weld Joints

Applications

The Techno Arc POU Heat Exchanger is a compact point-of-use cooler for Water For Injection (WFI) or Purified Water (PW) systems.

The POU Heat Exchanger meets the stringent hygiene standards imposed by both control authorities and industry.

Heat Exchanger is supplied as a complete insulated module with a pitot tubearrangement and either manual or automatic valves.

A typical duty for the POU Heat Exchanger is to cool WFI/water from 80-85ºC to 25-35ºC

Hygienic design

The POU Heat Exchanger is based on an innovative tube-in-tube design. All product wetted parts in the POU are SS 316L seamless electropolished tubes.

If needed, the POUHeat Exchanger is easy to clean and it can be steam sterilized.

There are no internal welds in the POU Heat Exchanger, eliminating the risk of cross contamination between the product and the service Medium.

The POU Heat Exchanger is fully drainable on the product side, with no dead legs in the complete module.

Lower total pressure drop

The POU Heat Exchanger Pitot tube arrangement ensures that throttling valves are not needed at every sub-loop, significantly reducing the total pressure drop of the water system.

Minimum Maintenance

The POU Heat Exchanger is virtually maintenance free with no internal gaskets. This reduces the downtime of the water system to a minimum.

Working principles

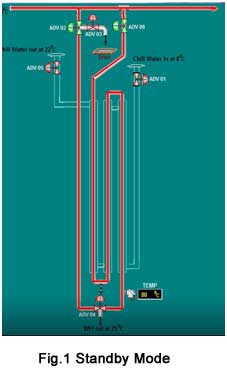

To maintain optimum sanitary conditions when the point-of-use cooler is in ‘stand-by’ mode, hot water from the main loop enters via the pitot tube and flows continuously through the point-of-use & back to the main loop (fig.1)

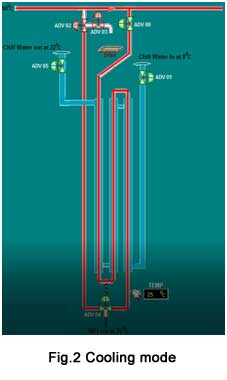

Switching from ‘stand-by mode’ to ‘cooling mode’ (fig.2). enables cold WFI or PW to be withdrawn within a few seconds. It is also possible to withdraw hot WFI or PW at the point of use. The low hold up volume, and the quick response of the heat exchanger, ensures that waste of WFI or PW is minimized. The cooling water demand is very low thanks to the efficient heat transfer.

Documentation

The POU Heat Exchanger is delivered along with a standard documentation including drawings, material certificates, operation and maintenance manual, pressure test certificate, welder’s certificates, Boroscopy Report, etc.

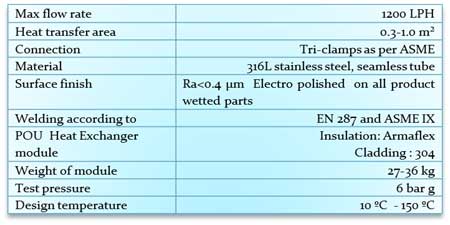

Technical data